Information and Process Modeling for Simulation – Part II: Activities and Processing Networks

This tutorial article is Part II of a series of three articles starting with Information and Process Modeling for Simulation – Part I: Objects and Events.

Copyright © 2019-2121 Gerd Wagner (CC BY-NC)

Published 2021-03-10. Also available as PDF.

Abstract

This article (1) reports new research results in the area of business process modeling and simulation, and (2) shows, in the style of a tutorial, how to use UML Class Diagrams and BPMN-style Process Diagrams for modeling Activities and Processing Networks. The state structure of a system is captured by a UML class model, which defines the types of objects, events and activities underlying a BPMN-style process model that captures the dynamics of the system in the form of a set of event rules. Part I of the tutorial presents the Object Event (OE) Modeling and Simulation (M&S) paradigm and the Discrete Event Process Modeling Notation (DPMN) as well as a basic OEM&S approach for modeling discrete event simulations (DES) with the help of OE class models and DPMN process models. In this second part, the basic OEM&S approach is extended by considering Activities and Processing Networks. Part III will show how to add the modeling concepts of Agents with Perceptions, Actions and Beliefs, resulting in a general agent-based Discrete Event Simulation modeling framework.

Table of Contents

List of Figures

- 1-1. A conceptual information model of a manufacturing workstation system

- 1-2. A conceptual process model of a manufacturing workstation system

- 1-3. An information design model

- 1-4. A process design model in the form of a DPMN Process Diagram

- 1-5. An ontology of the core categories of individuals of the OEM&S paradigm

- 1-6. A model of the core classes of individuals an OE simulator has to deal with at runtime.

- 1-7. A process design model in the form of a basic DPMN Process Diagram

- 1-8. An information design model in the form of a basic OE class model

- 1-9. A DPMN-A process model and its underlying OE class model

- 1-10. A DPMN-A process model with a resource-dependent activity start arrow and its underlying OE class model

- 1-11. A DPMN-A process model of a Load-Haul-Dump business process

- 1-12. A process design for the Make-and-Deliver-Pizza business process.

- 1-13. An enriched process design model

- 1-14. A process design for the Make-and-Deliver-Pizza business process.

- 2-1. Introducing an activity type in a conceptual information model of a single workstation system.

- 2-2. Introducing an activity type in a conceptual process model of a single workstation system.

- 2-3. Going from basic OEM to OEM-A class models by introducing activity types.

- 2-4. Going from basic DPMN to DPMN-A process models by introducing Activity rectangles.

- 2-5. Allocating the workstation as a resource of Processing activities

- 3-1. The resources required for performing an activity include the activity's performer.

- 3-2. Activity types may have special properties representing resource roles.

- 3-3. A conceptual information model of the activity type "examinations" with resource roles.

- 3-4. A conceptual process model based on the information model of Figure 3-3.

- 3-5. A conceptual information model with doctors and patients as people.

- 3-6. Adding the activity type "walks to room" to the conceptual information model.

- 3-7. A conceptual process model based on the information model of Figure 3-6.

- 3-8. An improved process model based on the information model of Figure 3-6.

- 3-9. Displaying the process owner and activity performers in a conceptual process model.

- 3-10. Adding parallel participation multiplicities for rooms participating both in walks and examinations at the same time.

- 3-11. An information model for the simplified design with the resource counters nmrOfRooms and nmrOfDoctors.

- 3-12. A process design model based on the information design model of Figure 3-11.

- 3-13. An OEM-A class model with resource object types for modeling resource roles and pools.

- 3-14. A process design model based on the information design model of Figure 3-13.

- 3-15. Any resource type R extends the pre-defined object type

Resource - 3-16. A simplified version of the model of Figure 3-13

- 3-17. An OE Class Diagram modeling a single workstation system with resource-constrained processing activities

- 3-18. An information design model for decoupling the allocation of rooms and doctors.

- 3-19. A process design model based on the information design model of Figure 3-18.

- 3-20. Representing the process owner as a Pool and activity performers as Lanes in a process design model.

- 3-21. A conceptual modeling pattern for a sequence of resource-constrained activities

- 3-22. Using resource-dependent activity start arrows in a conceptual process model.

- 3-23. Displaying the implicit allocate-release steps.

- 3-24. Modeling WorkStation as a resource type

- 3-25. A simplified version of the workstation process model using a resource-dependent activity start arrow.

- 3-26. A simplified version of the medical department information model with Doctor and Room as resource types

- 3-27. A simplified version of the medical department process model using resource-dependent activity start arrows.

- 4-1. Resource-constrained activities involving processing objects are processing activities.

- 4-2. A conceptual OEM class model defining built-in types for conceptual PN modeling

- 4-3. A PN model using the new DPMN modeling elements of PN Node rectangles and PN Flow arrows

- 4-4. A DPMN-PN process diagram with an Event Scheduling arrow

- 4-5. An OEM class design model defining built-in types for making PN design models

- 4-6. A PN model of a workstation system using PN Node rectangles and PN Flow arrows

- 4-7. A PN model of a workstation system where parts may have to be reworked

- 4-8. A PN model using the new DPMN modeling elements of PN Node rectangles and PN Flow arrows

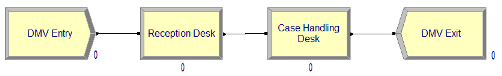

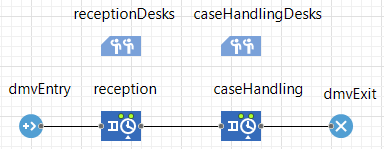

- 4-9. An Arena diagram for the DMV model

- 4-10. An AnyLogic diagram for the DMV model (imposing Java naming syntax)

List of Tables

Chapter 1. Introduction

Object Event (OE) Modeling and Simulation (M&S) is a new general Discrete Event Simulation (DES) paradigm based on the two most important ontological categories: objects and events. In philosophy, objects have also been called endurants or continuants, while events have also been called perdurants or occurrents.

OEM&S combines Object-Oriented (OO) Modeling with the event scheduling paradigm of Event Graphs (Schruben 1983). The relevant object types and event types are described in an information model, which is the basis for making a process model. A modeling approach that follows the OEM paradigm is called an OEM approach. Such an approach needs to choose, or define, an information modeling language (such as Entity Relationship Diagrams or UML Class Diagrams) and a process modeling language (such as UML Activity Diagrams or BPMN Process Diagrams).

We propose an OEM approach based on UML Class Diagrams for conceptual information modeling and information design modeling, as well as DPMN Process Diagrams for conceptual process modeling and for process design modeling.

In the proposed approach, object types and event types are modeled as special categories of classes in a UML Class Diagram. Random variables are modeled as a special category of class-level operations constrained to comply with a specific probability distribution such that they can be implemented as static methods of a class. Queues are not modeled as objects, but rather as ordered association ends, which can be implemented as collection-valued reference properties. Finally, event rules, which include event routines, are modeled in DPMN process diagrams (and possibly also in pseudo-code), such that they can be implemented in the form of special onEvent methods of event classes.

Like Petri Nets and DEVS, OEM&S has a formal semantics. But while Petri Nets and DEVS are abstract computational formalisms without an ontological foundation, OEM&S is based on the ontological categories of objects, events and causal regularities.

An OEM approach results in a simulation design model that has a well-defined operational semantics in terms of a transition system based on the event rules modeled in a DPMN process design diagram, as shown by Wagner (2017a). Such a model can, in principle, be implemented with any object-oriented (OO) simulation technology. However, a straightforward implementation can only be expected from a technology that implements the OEM&S paradigm, such as the OES JavaScript (OESjs) framework.

Both conceptual models for DES and DES design models consist of (1) an information model and (2) a process model. In the case of conceptual modeling, an information model describes the types of objects and events representing the main entities of the real-world system under investigation, while a process model describes its dynamics in the form of a set of conceptual event rule models that capture the causal regularities of the system.

In the case of simulation design modeling, an information design model defines the types of all objects and events that are relevant for the purpose of a simulation study, thus defining the state structure of a DES system, while a process design model defines the dynamics of a DES system by defining, for all event types of the underlying information model, an event rule design model that specifies the state changes and follow-up events implied by the occurrence of an event of that type.

In the first part of this article series, (Wagner 2018b), we have introduced a variant of the Business Process Modeling Notation (BPMN), called Discrete Event Process Modeling Notation (DPMN), and have shown how to use UML Class Diagrams and DPMN Process Diagrams for making basic OE models defining a set of object types OT, a set of event types ET, and a set of event rules R. In (Wagner 2017a), we have shown that (a) these three sets define a state transition system, where the state space is defined by OT and ET, and the transitions are defined by R, and (b) such a transition system represents an Abstract State Machine in the sense of Gurevich (1985). This fundamental characterization of an OE model provides a formal (operational) semantics for OE Simulation (OES) by defining an OES formalism that any OE simulator has to implement.

In this second part, we extend basic OEM/DPMN in two steps by adding support for (1) resource-constrained activities and (2) GPSS/SIMAN/Arena-style processing activities and processing networks (PNs).

Modeling resource-constrained activities has been a major issue in DES since its inception in the nineteen-sixties, while it has been neglected and is still considered an advanced topic in the field of Business Process Modeling (BPM). BPMN only provides partial support for modeling resource-constrained activities. It allows assigning resources to activities, but it does not allow modeling resource pools, and it does neither allow specifying resource cardinality constraints nor parallel participation multiplicity constraints.

Processing objects enter PNs via arrival events at an entry node and then flow through one or more processing nodes where they are subject to processing activities before they leave the system at an exit node via a departure event. The first extension, OEM/DPMN-A, comprises five new information modeling categories ("stereotypes") and one new process modeling element, while the second extension, OEM/DPMN-PN, comprises a set of four pre-defined object types and three pre-defined event types, three new (node type) categories and one new process modeling element, as listed in tables in Appendix A: OEM Elements.

1.1. Object Event Modeling

1.1.1. Example: A Manufacturing Workstation Model

A manufacturing workstation receives parts and stores them in its input buffer for processing them successively.

Conceptual Model

A conceptual information model of a workstation system, defining two object types and four event types, is shown in Figure 1-1.

As expressed by the associations between the four event types and the two object types, for all four types of events, there are the same two types of objects participating in them: parts and workstations, implying that each event of these four types involves a specific part and a specific workstation.

Notice that the input buffer (filled with waiting parts) is modeled as an association end with name waiting parts at the parts side of the association between parts and workstations, expressing the fact that at any point in time, a workstation has zero or more parts waiting in its input buffer for being processed.

A conceptual process model of this system, describing four causal regularities in the form of event rules, one for each type of event, is shown in Figure 1-2 in the form of a BPMN Process Diagram using Event circles connected with Sequence Flow arrows expressing (conditional) causation, and Data Objects attached to Event circles.

The four event rules described by this model are

- When a part arrives, it is added to the input buffer and, if the workstation is available, there will be a processing start event for processing the newly arrived part.

- When a processing start event occurs, the next part from the input buffer is being processed and a processing end event is caused to occur some time later (after the processing time has elapsed).

- When a processing end event occurs, this will cause a part departure event and, if the input buffer is not empty, another processing start event involving the next part from the buffer.

- When a part departure event occurs, the processed part will be removed from the workstation.

Design Model

A simulation design model is based on a conceptual model. Depending on the purposes/goals of a simulation study, it may abstract away from certain elements of the real-world domain described by the conceptual model, and it adds computational elements representing design decisions, such as random variables expressed int he form of random variate sampling functions based on specific probability distributions for modeling the random variation of certain system variables.

An information design model of the single workstation system described above is shown in Figure 1-3. This model defines the multi-valued waitingParts association end to be ordered, which means that it corresponds to a multi-valued reference property holding an ordered collection (such as an array list or a queue) as its value.

The information design model of Figure 1-3 defines that a PartArrival event must reference both a Part and a WorkStation, representing situations where specific parts arrive at specific workstations. Notice that, computationally, this model requires creating new Part objects (or retrieving them from an object pool) before a new PartArrival event is created (or scheduled), while it is more common in simulation models to create a new Part object only when an arrival event has occurred, which can be modeled by defining a multiplicity of 0..1 for the Part end of the PartArrival-Part association (with the meaning that PartArrival has an optional, instead of a mandatory, reference property with name part).

Notice that the model defines two class level operations (designated with the stereotype «rv») implementing random variate sampling functions: PartArrival::recurrence() complies with a triangular probability distribution with minimum, mode and maximum parameter values 3, 4 and 8, while ProcessingStart::processingTime() complies with an exponential distribution with a mean of 6.

A process design model based on the object and event types defined by the information design model of Figure 1-3 and derived from the conceptual process model of Figure 1-2 is shown in Figure 1-4.

Notice that, since all events happen at the same workstation, all three event scheduling arrows are annotated with the same event property assignment workStation := ws, which simply propagates the object reference to the given workstation along the event scheduling chain. Such property propagation assignments (in event property assignment annotations), where a property value of a follow-up event is set to the corresponding property value of the scheduling (or triggering) event, will be omitted (as implied by event types having the same property names) for avoiding to clutter the process model diagrams.

A DPMN Process Diagram, like the one shown in Figure 1-4, can be split up into a set of event rule diagrams, one for each of its Event circles, as shown in the following table. This reduction of a DPMN process design model to a set of event rule design models, together with the operational semantics of event rules presented in (Wagner 2017a), provides the semantics of DPMN Process Diagrams.

Notice that an event rule design model can also be expressed textually in the form of a pseudo-code block with four parts: part 1 indicates the triggering event type and declares a rule variable representing the triggering event, part 2 declares further rule variables and initializes them, part 3 contains a state change script consisting of state change statements, and part 4 schedules follow-up events.

| Rule design model | Pseudo-code | ||||

|---|---|---|---|---|---|

| |||||

| |||||

|

1.2. Ontological Considerations

Ontologically, an activity is a composite event (composed of at least a start and an end event) with a duration greater than zero, performed by an agent (a human or another living being, a robot or another artificial agent, or an organization or another social agent). As opposed to activities, activity start and end events are instantaneous (zero-duration) events.

As an event, an activity has objects that participate in it. In the real world, an activity has at least one participant: the performer of the activity. Consequently, a conceptual model should, for each activity type, include the type of objects that play the performer role for activities of that type, as described by the UML class diagram shown in Figure 1-5.

However, in a simulation design model we may choose to leave the performer of an activity implicit and model an activity without modeling any participant. Consequently, a basic OE simulator, the core classes of which are described in Figure 1-6, does not need to support the distinction between objects and agents.

1.3. Object Event Simulation

The Object Event Simulation (OES) paradigm is an extension of the Event-Based Simulation (ES) paradigm pioneered by SIMSCRIPT (Markowitz, Hausner & Karr 1962) and later formalized by Event Graphs (Schruben 1983). Essentially, OES extends ES, or Event Graphs, by adding the modeling concepts of objects and event rules.

Starting with an initial simulation state, an OE model is executed by successively applying the event rules of the model to the evolving simulation states.

Notice that the occurrence time of an activity is the time when it completes, that is, it is equal to startTime + duration. Typically, the duration of an activity in a simulation run is known, and set, when it is started. An activity type is normally defined with a fixed duration or a random variable duration for all activities of that type. This allows a simulator to schedule the activity's end event when the activity is started. However, in certain cases, an activity type may not define a preset duration, but leave the duration of activities of that type open. When such an activity is still ongoing, it does only have a start time, but no duration and no occurrence time.

The OES formalism

The OEM&S paradigm is based on the OES formalism presented in (Wagner 2017a), which is summarized below.

Both object types and event types are defined in the form of classes: with a name, a set of properties and a set of operations, which together define their signature. A property is essentially defined by a name and a range, which is either a datatype (like Integer or String) or another object type.A set of object types OT defines a predicate-logical signature as the basis of a logical expression language LOT: each object type defines a unary predicate, and its properties define binary predicates. A state change language COT based on OT defines state change statements expressed with the help of the object type names and property names defined by OT. In the simplest case, state change statements are property value assignments like o.p1 := 4 or o.p1 := o.p2 where o is an object variable and p1, p2 are property names.

A set of objects O = {o1, o2, ...on} where each of them has a state in the form of a set of slots (property-value pairs) represents a system state, that is a state of the real-world system being modeled and simulated. A system state O can be updated by a set of state changes (or, more precisely, state change statements) Δ ⊆ COT with the help of an update operation Upd. For instance, for a system state O1 = {o1} with o1 = { p1: 2, p2: 5} and a set of state changes Δ1 = { o1.p1 := o1.p2 } we obtain

An event expression is a term E(x)@t where

- E is an event type,

- x is a (possibly empty) list of event parameters x1, x2, …, xn according to the signature of the event type E,

- t is a parameter for the occurrence time of events.

For instance, PartArrival(ws)@t is an event expression for describing part arrival events where the event parameter ws is of type WorkStation, and t denotes the arrival time. An individual event of type E is a ground event expression, e = E(v)@i, where the event parameter list x and the occurrence time parameter t have been instantiated with a corresponding value list v and a specific time instant i. For instance, PartArrival(ws1)@1 is a ground event expression representing an individual PartArrival event occurring at workstation ws1 at time 1.

A Future Events List (FEL) is a set of ground event expressions partially ordered by their occurrence times, which represent future time instants either from a discrete or a continuous model of time. The partial order implies the possibility of simultaneous events, as in the example {ProcessingEnd(ws1)@4, PartArrival(ws1)@4}.An event routine is a procedure that essentially computes state changes and follow-up events, possibly based on conditions on the current state. In practice, state changes are often directly performed by immediately updating the objects concerned, and follow-up events are immediately scheduled by adding them to the FEL. For the OES formalism, we assume that an event routine is a pure function that computes state changes and follow-up events, but does not apply them, as illustrated by the examples in the following table.

Event rule name / rule variables | ON (event expression) | DO (event routine) |

rPA a: PartArrival | PartArrival(ws) @ t | Δ := { ws.waitingParts.push( a.part)} IF ws.status = AVAILABLE RETURN ⟨ Δ, FE ⟩ |

rPS ps: ProcessingStartws: WorkStation ws := ps.workStation | ProcessingStart(ws) @ t | Δ := { ws.status := BUSY} FE := {ProcessingEnd(ws)@t + ProcessingStart.processingTime()} RETURN ⟨ Δ, FE ⟩ |

rPE pe: ProcessingEndws: WorkStation ws := pe.workStation | ProcessingEnd(ws) @ t | Δ := { ws.waitingParts.pop()} IF ws.waitingParts.length > 0 RETURN ⟨ Δ, FE ⟩ |

An event rule associates an event expression with an event routine F:

where the event expression E(x)@t specifies the type E of events that trigger the rule, and F( t, x) is a function call expression for computing a set of state changes and a set of follow-up events, based on the event parameter values x, the event's occurrence time t and the current system state, which is accessed in the event routine F for testing conditions expressed in terms of state variables.

An OE model based on a state change language COT and a corresponding update operation Upd is a triple ⟨OT, ET, R⟩, consisting of a set of object types OT, event types ET and event rules R.

An OE simulation (system) state based on an OE model ⟨OT, ET, R⟩ is a triple S = ⟨t, O, E⟩ with t being the current simulation time, O being a system state (a set of objects instantiating types from OT), and E being a set of imminent events to occur at times greater than t (and instantiating types from ET), also called Future Event List (FEL).An event rule r = ON E(x)@t DO F( t, x) can be considered as a 2-step function that, in the first step, maps an event e = E(v)@i to a parameter-free state change function re = F( i, v), which maps a system state O to a pair ⟨ Δ, FE ⟩ of system state changes Δ ⊆ COT and follow-up events FE. When the parameters t and x of F( t, x) are replaced by the values i and v provided by a ground event expression E(v)@i, we also simply write Fi,v instead of F( i, v) for the resulting parameter-free state change function.

We say that an event rule r is triggered by an event e when the event's type is the same as the rule's event type. When r is triggered by e, we can form the state change function re = Fi,v and apply it to a system state O by mapping it to a set of state changes and a set of follow-up events:

We can illustrate this with the help of our workstation example. Consider the rule rPA defined in the table above triggered by the event PartArrival(ws1)@1 in state O0 = {ws1.status: AVAILABLE, ws1.waitingParts: []}. We obtain

with Δ1 = { ws1.waitingParts.push( a.part)} and FE1 = {ProcessingStart@2}.

An OE model defines a state transition system where

A state is a simulation state S = ⟨t, O, E⟩.

A transition of a simulation state S consists of

advancing t to the occurrence time t' of the next events NE ⊆ E, which is the set of all imminent events with minimal occurrence time;

processing all next events e ∈ NE by applying the event rules r ∈ R triggered by them to the current system state O according to

re( O ) = ⟨ Δe , FEe ⟩resulting in a set of state changes Δ = ∪ {Δe | e ∈ NE } and a set of follow-up events FE = ∪ {FEe | e ∈ NE }.

such that the resulting successor simulation state is S' = ⟨ t', O', E' ⟩ with O' = Upd( O, Δ) and E' = E − NE ∪ FE.

Notice that the OES formalism first collects all state changes brought about by all the simultaneous next events (from the set NE) of a simulation step before applying them. This prevents the state changes brought about by one event from NE to affect the application of event rules for other events from NE, thus avoiding the problem of non-determinism through the potential non-confluence (or non-serializability) of parallel events.

OE simulators are computer programs that implement the OES formalism. Typically, for performance reasons, discrete event simulators do not first collect all state changes brought about by all the simultaneous next events (the set NE) of a simulation step before applying them, but rather apply them immediately in each triggered event routine. However, this approach takes the risk of an unreliable semantics of certain simulation models in favor of performance.

OESjs – a JavaScript-based OE simulator

The OESjs simulator presented in (Wagner 2017b) implements the OES formalism by implementing (1) object types as classes extending the pre-defined class oBJECT, (2) event types as classes extending the pre-defined class eVENT, and (3) event rules as onEvent methods of event classes.

The OESjs simulator is available from the educational simulation website sim4edu.com.

1.4. Discrete Event Processes, Business Processes and Processing Processes

A discrete event process consists of a partially ordered set of events that cause a corresponding sequence of discrete state changes of affected objects. When two or more events within such a process have the same order rank, this means that they occur simultaneously. A discrete event process, also known more simply as a discrete process, may be an instance of a discrete process type defined by a discrete process model.

A business process is a discrete process that serves certain business purposes of an organization and involves events and activities performed by actors of the organization. Typically, a business process is an instance of a business process type defined by an organization (or organizational unit), which is the owner of the business process type, in the form of a business process model.

A business process model defines an Activity Network (AN) consisting of event and activity nodes connected by means of event flow arrows and resource-dependent activity scheduling (RDAS) arrows, such that event and activity nodes may be associated with objects representing their participants. In the case of an activity node, these participating objects include the resource objects required for performing an activity. Typically, an activity node is associated with a particular resource object representing the activity performer.

An RDAS arrow from an activity node (or an event) to a successor activity node expresses the fact that a corresponding activity end event (or plain event) triggers the conditional scheduling of a successor activity start event, corresponding to the creation of a new task in the task queue of (the performer of) the successor activity.

An activity node of an AN typically has a queue of tasks (or planned activities) waiting for the availability of the required resources.

A processing process is a business process involving arrival events, processing activities and departure events. An arrival event for one or more processing objects happens at an entry station, from where they are routed to a processing station where processing activities are performed on them, before they are routed to another processing station or to an exit station where they leave the system via a departure event.

A processing process model defines a Processing Network (PN) consisting of entry nodes, processing nodes and exit nodes where each node represents a combination of a spatial object and an event type:

- Defining an entry node means defining both an entry station object (e.g., a reception area or a factory entrance) and an arrival event type for arriving processing objects (such as people or manufacturing parts).

- Defining a processing node means defining both a processing station object (often used as a resource object, such as a workstation or a room) and a processing activity type.

- Defining an exit node means defining both an exit station object and a departure event type.

In a PN, all processing nodes have an input buffer (or queue) filled with processing objects that wait to be processed. A PN where all processing activities have exactly one abstract resource (a "server") is also known as a Queuing Network in Operations Research (where processing nodes are called "servers" and processing objects are called "entities" or "jobs").

For accommodating resource-constrained activities and Processing Networks, basic OEM and DPMN are extended in two steps. The first extension, OEM/DPMN-A, comprises four new information modeling categories (activity types, resource roles, resource pools, and parallel participation) and one new process modeling element (RDAS arrows), while the second extension, OEM/DPMN-PN, comprises a set of four pre-defined object type categories (processing objects, entry stations, processing stations, exit stations), two pre-defined event type categories (arrival events, departure events), one activity type category (processing activities), three node type categories (entry nodes, processing nodes, exit nodes) and one new process modeling element (object flow arrows).

A. Discrete Event Processes and Event Graphs

A discrete event process consists of a partially ordered set of events that cause a corresponding sequence of discrete state changes of affected objects. When two or more events within such a process have the same order rank, this means that they occur simultaneously.

As an example of a discrete event process we consider a manufacturing process with a workstation and three types of events: PartArrival events, ProcessingStart events and ProcessingEnd events.

The example process is described by the following list of event expressions: PartArrival@1, [email protected], [email protected], [email protected], [email protected], [email protected], [email protected], [email protected], [email protected], where an expression E@t represents an event of type E occurring at time t.

How this process unfolds in time is illustrated by the following process log:

| Step | Time | System State | Future Events |

|---|---|---|---|

| 0 | 0 | WorkStation-1{ bufLen: 0, status: "AVAILABLE"} | PartArrival@1 |

| 1 | 1 | WorkStation-1{ bufLen: 1, status: "AVAILABLE"} | [email protected], [email protected] |

| 2 | 1.01 | WorkStation-1{ bufLen: 1, status: "BUSY"} | [email protected], [email protected] |

| 3 | 5.4 | WorkStation-1{ bufLen: 2, status: "BUSY"} | [email protected], [email protected] |

| 4 | 6.5 | WorkStation-1{ bufLen: 3, status: "BUSY"} | [email protected] |

| 5 | 8.47 | WorkStation-1{ bufLen: 2, status: "BUSY"} | [email protected] |

| 6 | 8.48 | WorkStation-1{ bufLen: 2, status: "BUSY"} | [email protected] |

| 7 | 11.95 | WorkStation-1{ bufLen: 1, status: "BUSY"} | [email protected] |

| 8 | 11.96 | WorkStation-1{ bufLen: 1, status: "BUSY"} | [email protected] |

| 9 | 17.48 | WorkStation-1{ bufLen: 0, status: "AVAILABLE"} |

The events of a real-world discrete event process happen in a coherent spatio-temporal region determined by the locations of the events' participants. In a simulation model, one may abstract away from the aspect of space and model objects without locations, implying that events and processes happen in time, but not in space.

A discrete event process, also known more simply as a discrete process, may be an instance of a discrete process type defined by a discrete process model. A discrete event process pattern can be modeled in the form of a basic DPMN process diagram, which is an extended Event Graph.

The Event Graph modeling language proposed by Schruben (1983) defines directed graphs where the nodes are Event circles (representing typed event variables) annotated with state change statements in the form of state variable assignments, and the edges are arrows representing event flows. In the case of a conceptual process model, event flow arrows express the causation of follow-up events. In the case of a process simulation design model, event flow arrows express the scheduling of follow-up events according to the event scheduling paradigm of Discrete Event Simulation.

Basic DPMN extends the Event Graph diagram language by adding object rectangles containing declarations of typed object variables and state change statements, as well as gateway diamonds for expressing conditional and parallel branching.

The following basic DPMN diagram is an extended Event Graph defining a process pattern that is instantiated by the above discrete event process example.

This process model is based on the following Object Event (OE) class model:

A DPMN process design model specifies a set of chained event rules, one rule for each Event circle of the model. The above model specifies the following three event rules:

- On each PartArrival event, the inputBufferLength attribute of the associated WorkStation object is incremented and if the workstation's status attribute has the value AVAILABLE, then a new ProcessingStart event is scheduled to occur immediately.

- When a ProcessingStart event occurs, the associated WorkStation object's status attribute is changed to BUSY and a ProcessingEnd event is scheduled with a delay provided by invoking the processingTime function defined in the ProcessingStart event class.

- When a ProcessingEnd event occurs, the inputBufferLength attribute of the associated WorkStation object is decremented and if the inputBufferLength attribute has the value 0, the associated WorkStation object's status attribute is changed to AVAILABLE. If the inputBufferLength attribute has a value greater than 0, a new ProcessingStart event is scheduled to occur immediately.

The formal (transition system) semantics of basic DPMN diagrams, based on the semantics of event rules as transition functions, has been presented in (Wagner 2017a). It can be shown that the basic DPMN diagram language is a conservative extension of the Event Graph diagram language by means of a homomorphic embedding of Event Graphs in DPMN diagrams.

B. Business Processes and Activity Networks

An activity is a composite event that is composed of, and temporally framed by, a pair of start and end events.

A business process of an organization is a discrete event process that includes activities performed by actors of the organization for serving certain business purposes of the organization. In addition to its performer, an activity may involve further resources, and allocating the required resources from resource pools during the course of a business process is essential for keeping it going.

As an example of a business process we consider a manufacturing process with a workstation and three types of events: PartArrival events, Processing-Activity-Start events and Processing-Activity-End events.

The example business process is described by the following list of event expressions: PartArrival@1, [email protected], [email protected], [email protected], [email protected], [email protected], [email protected], [email protected], [email protected], where an expression E@t represents an event of type E occurring at time t.

How this process unfolds in time is illustrated by the following process log:

| Step | Time | System State | Future Events |

|---|---|---|---|

| 0 | 0 | WorkStation-1{ status: 1} | av. workStations: ws1 | PartArrival@1 |

| 1 | 1 | WorkStation-1{ status: 2} | av. workStations: | Processing-Activity-Start{ ws1 }@1.01, [email protected] |

| 2 | 1.01 | WorkStation-1{ status: 2} | av. workStations: | Processing-Activity-End{ ws1 }@8.08, [email protected] |

| 3 | 8.08 | WorkStation-1{ status: 1} | av. workStations: ws1 | [email protected] |

| 4 | 18.83 | WorkStation-1{ status: 2} | av. workStations: | Processing-Activity-Start{ ws1 }@18.84, [email protected] |

| 5 | 18.84 | WorkStation-1{ status: 2} | av. workStations: | Processing-Activity-End{ ws1 }@23.9, [email protected] |

| 6 | 23.9 | WorkStation-1{ status: 1} | av. workStations: ws1 | [email protected] |

| 7 | 25.61 | WorkStation-1{ status: 2} | av. workStations: | Processing-Activity-Start{ ws1 }@25.62 |

| 8 | 25.62 | WorkStation-1{ status: 2} | av. workStations: | Processing-Activity-End{ ws1 }@32.03 |

| 9 | 32.03 | WorkStation-1{ status: 1} | av. workStations: ws1 |

Notice that, as opposed to the process log shown in Table 1-1,

- the workstation with ID 1 is a (performer) resource for Processing activities having either the status 1 (being available) or 2 (being busy), and

- there is a pool of available resources ("av. workStations").

Typically, a business process is an instance of a business process type defined by an organization (or organizational unit), which is the owner of the business process type, in the form of a business process model. The above example business process is an instance of the following model:

A business process model defines an Activity Network (AN), which provides a pattern for business processes. An AN specifies a set of chained event rules with typed object, event and activity variables, based on an OE class model defining object, event and activity types. By convention, activity classes have a duration function that is invoked for getting the duration of newly created instances of the activity class. In a simulation design model, these functions typically define random variate sampling functions (like the service time concept in queuing theory).

Event circles and Activity rectangles may be connected via event flow arrows, as shown above in Figure 1-9, or via resource-dependent activity scheduling arrows, as shown below in Figure 1-10.

The AN shown in Figure 1-9 defines the following event rules:

- On each PartArrival event, if the associated WorkStation object's status attribute has the value AVAILABLE, then it is set to BUSY and the rule variable wsAllocated is set to true; otherwise the inputBufferLength attribute of the associated WorkStation object is incremented. If wsAllocated holds, then a new Processing activity is scheduled to start immediately with a duration provided by invoking the duration function defined in the Processing activity class.

- When a Processing activity ends, if the inputBufferLength attribute of the associated WorkStation object has the value 0, then the WorkStation object's status attribute is set to AVAILABLE; otherwise the rule variable wsAllocated is set to true and the WorkStation object's inputBufferLength attribute is decremented. If wsAllocated holds, then a new Processing activity is scheduled to start immediately with a duration provided by invoking the duration function defined in the Processing activity class.

Since the resource management logic concerning the workstation as a resource for Processing activities follows a general pattern, a new modeling language element can be introduced for capturing this pattern. Using resource-dependent activity start arrows, we can express the process model of Figure 1-9 more simply as in the following diagram:

Notice that in this model, we have expressed that we no longer have to take care of setting the status of the workstation as a resource, nor do we have to update the queue/buffer length. This is now expressed implicitly by the semantics of the resource-dependent activity scheduling (RDAS) arrow and has to be handled in a generic way by a simulator supporting DPMN-A models.

The following diagram shows a model containing both event scheduling arrows and RDAS arrows:

In this model, activities are initiated (1) by an RDAS arrow when they may have to wait for the availability of required resources, or (2) by an event scheduling arrow when no other resources are required. For instance, a new Load activity can only be started, when a wheel loader (as a performer) is available, while a Haul activity can be started immediately after the completion of a Load activity because it's performed by the loaded truck, and no other resources are required.

The most widely used language for defining ANs is the Business Process Modeling Notation (BPMN). However, in BPMN there is only one type of arrow, called "Sequence Flow", which is semantically overloaded with both meanings: it can represent an event flow arrow or a resource-dependent activity start arrow.

The concept of ANs includes business system processes, where many business actors perform activities for handling many business cases in parallel. Consequently, it is more general than the common concept of a business process as a case-handling process.

Normally all activity nodes of an AN have a queue of planned activities ("tasks") waiting for the availability of required resources (in particular, their performer). Only if a successor activity node does not require additional or different resources, it does not have a (resource allocation) queue and can be started right away whenever a predecessor activity has completed, as indicated by an event flow arrow.

When all activity nodes of an AN only have a single resource (the performer of the activity), and each of them has a different performer, then the AN corresponds to a Queuing Network in the sense of Operations Research.

A DPMN process design model (like the one shown in Figure 1-12) essentially defines the admissible sequences of events and activities together with their dependencies and effects on objects, while its underlying OE class design model (like the one shown in Figure 1-14 below) defines the types of objects, events and activities, together with the participation of objects in events and activities, including the resource roles of activities, as well as resource cardinality constraints, parallel participation constraints, alternative resources, and task priorities.

It is an option, though, to enrich a DPMN process design model by displaying more computational details, especially the recurrence of exogenous events, the duration of activities and the most important resource management features defined in the underlying OE class design model, such as resource roles (in particular, performer roles can be displayed in the form of Lanes), resource cardinality constraints, alternative resources, and task priorities. The following model shows an enriched version of Figure 1-12:

Such an enriched DPMN process design model includes all computational details needed for an implementation without a separate explicit OE class design model. In fact, such a process model implicitly defines a corresponding class model. For instance, the enriched DPMN model of Figure 1-13 above implicitly defines the following OE class model:

C. Processing Processes and Processing Networks

T.B.D.

Chapter 2. Simple Activities

A simple activity is an activity with zero or more participants, none of which is having a special meaning (such as being a resource or a processing object).

2.1. Conceptual Modeling of Simple Activities

Conceptually, an activity is a composite event that is composed of, and temporally framed by, a pair of start and end events. Consequently, whenever a model contains a pair of related start and end event types, like processing start and processing end in the model of a manufacturing workstation shown on the left-hand side of Figure 2-1 and Figure 2-2, they can be replaced with a corresponding activity type, like processing, as shown on the right-hand side.

It is obvious that applying this replacement pattern leads to a conceptual and visual simplification of the models concerned.

2.2. Design Modeling of Simple Activities

Like in a conceptual model, also in a design model, a pair of corresponding activity start Event and end Event circles, like ProcessingStart and ProcessingEnd in the source models shown in Figure 2-3 and Figure 2-4, can be replaced with a corresponding Activity rectangle, like Processing, as in the target models shown in these figures.

Extending basic OEM information design models by adding activity types

In the case of an information design model, this replacement pattern implies allocating all features (attributes, associations and operations) of the classes defining the start and the end event type in the class defining the corresponding activity type, possibly with renaming some of them. In the example of Figure 2-3, there is only one such feature: the class-level operation ProcessingStart::processingTime, which is allocated to Processing and renamed to time.

Extending basic DPMN process design diagrams by adding Activity rectangles

In the case of a process design model, the replacement pattern implies that an Event circle pair consisting of an Event circle intended to represent activity start events and an Event circle intended to represent related activity end events, with an event scheduling arrow from the start to the end Event circle annotated by a delay expression, is replaced by an Activity rectangle such that:

- All Data Objects attached to the end Event circle get attached to the Activity rectangle (since an activity occurs when it it is completed).

- All event scheduling arrows going out from the end Event circle are turned into event scheduling arrows going out from the Activity rectangle.

- All start event scheduling arrows are replaced with corresponding activity scheduling arrows having an additional creation parameter assignment for the duration of a scheduled activity, which is set to the delay expression defined for the end event scheduling arrow. In the example above, the duration parameter in the annotation of the two activity scheduling arrows is set to

Processing::time()in the target diagram, which is the same as the delayProcessingStart::processingTimein the source diagram. - When the start Event circle has one or more attached Data Objects or any outgoing event scheduling arrow that does not go to the end Event circle, then a start Event circle has to be included in the Activity rectangle for attaching the Data Object(s) and as the source of the outgoing event scheduling arrow(s).

This Activity-Start-End Rewrite Pattern, which can also be applied in the inverse direction, replacing an Activity rectangle with an Event circle pair, defines the meaning of an Activity rectangle in a DPMN diagram. It allows reducing a DPMN-A diagram with Activity rectangles to a basic DPMN diagram without Activity rectangles.

Notice that, like the source model, also the target model of Figure 2-4 specifies three event rules:

- On each PartArrival event, the arrived part is added to the workstation's input buffer and if the workstation's status is AVAILABLE, then a new Processing activity is scheduled to start immediately with a duration provided by invoking the time function defined in the Processing activity class.

- When a Processing activity starts, the workstation's status is changed to BUSY.

- When a Processing activity ends, the processed part is removed from the input buffer and, if the input buffer is not empty, a new Processing activity is scheduled to start immediately, otherwise (if the input buffer is empty) the workstation's status is changed to AVAILABLE.

An alternative process design model of the single workstation system

Based on the same information design model, shown in Figure 2-3, we can make another process design model of the single workstation system as an alternative to the target model of Figure 2-4. This alternative model makes it more clear that a workstation is, in fact, an exclusive resource of its processing activity. The concepts of resources and resource-constrained activities are discussed in the following sections, and in Section 3.2, it is shown how to simplify the basic DPMN model of Figure 2-5 by using the higher-level modeling elements introduced in DPMN-A.

Chapter 3. Resource-Constrained Activities

A Resource-Constrained Activity is an activity where one or more participants play a Resource Role (such as Performer). Typically, a resource-constrained activity is a component of a business process that happens in the context of an organization or organizational unit, which is associated with the activity as its Process Owner.

An activity of a certain type may require certain resources for being performable. At any point in time, a resource required for performing an activity may be available or not. A resource is not available, for instance, when it is is busy or when it is out of order.

Resources are objects of a certain type. The resource objects of an activity include its performer, as expressed in the diagram shown in Figure 3-1. While in a conceptual model, describing a real-world system, a performer is required for any activity, a simulation design model may abstract away from the performer of an activity.

For instance, a consultation activity may require a consultant and a room. Such resource cardinality constraints are defined at the type level. When defining the activity type Consultation, these resource cardinality constraints are defined in the form of two mandatory associations with the object types Consultant and Room such that both associations' ends have the multiplicity 1 ("exactly one"). Then, in a simulation run, a new Consultation activity can only be started, when both a Consultant object and a Room object are available.

For all types of resource-constrained activities, a simulator can automatically collect the following statistics:

- Throughput statistics: the numbers of enqueued and dequeued planned activities, and the numbers of started and completed activities.

- Queue length statistics (average, maximum, etc.) of its queue of planned activities.

- Cycle time statistics (average, maximum, etc.), where cycle time is the sum of the waiting time and the activity duration.

- Resource utilization statistics: the percentage of time each resource object involved is busy with an activity of that type.

In addition, a simulator can automatically collect the percentage of time each resource object involved is idle or out-of-order.

For modeling resource-constrained activities, we need to define their types. As can be seen in Figure 3-2, a resource-constrained activity type is composed of

- a set of properties and a set of operations, as any entity type,

- a set of resource roles, each one having the form of a reference property with a name, an object type as range, and a multiplicity that may define a resource cardinality constraint like, e.g., "exactly one resource object of this type is required" or "at least two resource objects of this type are required".

The resource roles defined for an activity type may include the performer role.

These considerations show that a simulation language for simulating activities needs to allow defining activity types with two kinds of properties: ordinary properties and resource roles. At least for the latter ones, it must be possible to define multiplicities for defining resource cardinality constraints. These requirements are fulfilled by OE Class Diagrams where resource roles are defined as stereotyped properties using the stereotype «resource role» or, shorter, «res».

The extension of basic OEM by adding the concepts needed for modeling resource-constrained activities (in particular, resource roles with constraints, resource pools, and resource-dependent activity start arrows) is called OEM-A.

3.1. Conceptual Modeling of Resource-Constrained Activities

Modeling resource-constrained activities has been a major issue in the field of Discrete Event Simulation (DES) since its inception in the nineteen-sixties, while it has been neglected and is still considered an advanced topic in the field of Business Process Modeling (BPM). The concept of resource-constrained activities is at the center of both DES and BPM. But both fields have developed different, and even incompatible, concepts of business process simulation.In the DES paradigm of Processing Networks, Gordon (1961) has introduced the resource management operations Seize and Release in the simulation language GPSS for allocating and de-allocating (releasing) resources. Thus, GPSS has established a standard modeling pattern for resource-constrained activities, which has become popular under the name of Seize-Delay-Release indicating that for simulating a resource-constrained activity, its resources are first allocated, and then, after some delay (representing the duration of the simulated activity), they are de-allocated (released).

Resource roles, process owners and resource pools

As an illustrative example, we consider a hospital consisting of medical departments where patients arrive for getting a medical examination performed by a doctor. A medical examination, as an activity, has three participants: a patient, a medical department, and a doctor, but only one of them plays a resource role: doctors. This can be indicated in an OE Class Diagram by using the stereotype «resource role» for categorizing the association ends that represent resource roles, as shown in Figure 3-3.

Notice that both the event type patient arrivals and the activity type examinations have a (mandatory functional) reference property process owner. This implies that both patient arrival events and examination activities happen at a specific medical department, which is their process owner in the sense that it owns the process types composed of them. A process owner is called "Participant" in BPMN (in the sense of a collaboration participant) and visually rendered in the form of a container rectangle called "Pool".

In Figure 3-3, the resource role of doctors corresponds to the performer role. In BPMN, Performer is considered to be a special type of resource role. According to (BPMN 2011), a performer can be "a specific individual, a group, an organization role or position, or an organization".[1]In BPMN, the performer role is specialized into the HumanPerformer of an activity, which is, in turn, specialized into PotentialOwner denoting the "persons who can claim and work" on an activity of a given type. "A potential owner becomes the actual owner [...] by explicitly claiming" an activity. Allocating a human resource to an activity by leaving the choice to those humans that play a suitable resource role is characteristic for workflow management systems, while in traditional DES approaches to resource handling, as in Arena and AnyLogic, (human) resources are assigned to a task (as its performer) based on certain policies.

One of the main reasons for considering certain objects as resources is the need to collect utilization statistics (either in an operational information system, like a workflow management system, or in a simulation model) by recording the use of resources over time (their utilization) per activity type. By designating resource roles in information models, these models provide the information needed in simulations and information systems for automatically collecting utilization statistics.

In the hospital example, a medical department, as the process owner, is the organizational unit that is responsible for reacting to certain events (here: patient arrivals) and managing the performance of certain processes and activities (here: medical examinations), including the allocation of resources to these processes and activities. For being able to allocate resources to activities, a process owner needs to manage resource pools, normally one for each resource role of each type of activity (if pools are not shared among resource roles). A resource pool is a collection of resource objects of a certain type. For instance, the three X-ray rooms of a diagnostic imaging department form a resource pool of that department.

Resource pools can be modeled in an OE Class Diagram by means of special associations between object classes representing process owners (like medical departments) and resource classes (like doctors), where the association ends, corresponding to collection-valued properties representing resource pools, are stereotyped with «resource pool», as shown in Figure 3-3. At any point in time, the resource objects of a resource pool may be out of order (like a defective machine or a doctor who is not on schedule), busy or available.

A process owner has special procedures for allocating available resources from resource pools to activities. For instance, in the model of Figure 3-3, a medical department has the procedure "allocate a doctor" for allocating a doctor to a medical examination. These resource allocation procedures may use various policies, especially for allocating human resources, such as first determining the suitability of potential resources (e.g., based on expertise, experience and previous performance), then ranking them and finally selecting from the most suitable ones (at random or based on their turn). See also (Arias et al 2018).

The conceptual process model shown in Figure 3-4 is based on the information model above. It refers to a medical department as the process owner, visualized in the form of a Pool container rectangle, and to doctor objects, as well as to the event type patient arrivals and to the activity type examinations.

This process model describes two causal regularities in the form of the following two event rules, each stated with two bullet points: one for describing all the state changes and one for describing all the follow-up events brought about by applying the rule.

When a new patient arrives:

- if a doctor is available, then she is allocated to the examination of that patient; otherwise, a new planned examination is queued up;

- if a doctor has been allocated, then start an examination of the patient.

When an examination is completed by a doctor:

- if the queue of planned examinations is empty, then the doctor is released;

- otherwise, the next planned examination by that doctor is scheduled to start immediately.

These conceptual event rules describe the real-world dynamics of a medical department according to business process management decisions. Changes of the waiting line and (de-)allocations of doctors are considered to be state changes (in the, not necessarily computerized, information system) of the department, as they are expressed in Data Object rectangles, which represent state changes of affected objects caused by an event in DPMN.

Notice that the model of Figure 3-4 abstracts away from the fact that after allocating a doctor, patients first need to walk to the room before their examination can start. Such a simplification may be justified if the walking time can be neglected or if there is no need to maximize the productive utilization of doctors who, according to this process model, have to wait until the patient arrives at the room. Below, this model is extended for allowing to allocate rooms and doctors such that patients have to wait for doctors, and not the other way around.

Switching roles: doctors as patients

The same person who is a doctor at a diagnostic imaging department may be treated as a patient of that department. It's a well-known fact that in the real world people may switch roles and may play several roles at the same time, but many modeling approaches/platforms fail to admit this. For instance, the simulation language (SIMAN) of the well-known DES modeling tool Arena does not treat resources and processing objects ("entities") as roles, but as strictly separate categories. This language design decision was a meta-modeling mistake, as admitted by Denis Pegden, the main creator of SIMAN/Arena, in (Drogoul et al 2018) where he says "it was a conceptualization mistake to view Entities and Resources as different constructs".

In Figure 3-5, the above model is extended by categorizing the classes doctors and patients as «role type» classes and adding the «kind» class people as a supertype of doctors and patients, we create the possibility that a person may play both roles: the role of a doctor and the role of a patient, albeit not at the same time. The object type categories «kind» and «role type» have been introduced to conceptual modeling by Guizzardi (2005).

Queueing planned activities

Whenever an activity is to be performed but cannot start due to a required resource not being available, the planned activity is placed in a queue as a waiting job. Thus, in the case of a medical examination of a patient, as described in the model of Figure 3-5, the waiting line represents, in fact, a queue of planned examinations (involving patients), and not a queue of waiting patients.

This consideration points to a general issue: modeling resource-constrained activities implies modeling queues of planned activities, while there is no need to consider (physical) queues of (physical) objects. Consequently, even if a real-world system includes a physical queue (of physical objects), an OEM-A model may abstract away from its physical character and consider it as a queue of planned activities (possibly including pre-allocated resources). While a physical queue implies that there is a maximum capacity, a queue of planned activities does not imply this. For instance, when a medical department does not require patients to queue up in a waiting area for obtaining an examination, but accepts their registration for an examination by phone, the resulting queue of waiting patients is not a physical queue (but rather a queue of planned examinations) and there is no need to limit the number of waiting patients in the same way as in the case of queuing up in a waiting area with limited space.

A planned activity can only start, when all required resources have been allocated to it. Thus, a planned examination of a patient can only start, when both a room and a doctor have been allocated to it. Let's assume that when a patient p arrives, only a room is available, but not a doctor. In that case, the available room is allocated to the planned examination, which is then placed in a queue since it still has to wait for the availability of a doctor. Only when a doctor becomes available, e.g., via the completion of an examination of another patient or via an arrival of a doctor, the doctor can be allocated as the last resource needed to start the planned examination of patient p.

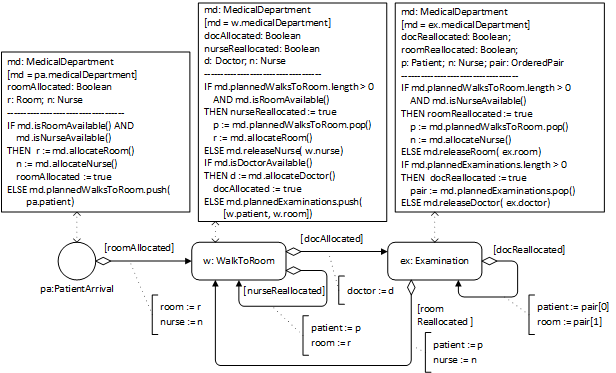

As a consequence of these considerations, the waiting line of a medical department modeled in Figure 3-5 as an ordered collection of patients is renamed to planned walks in Figure 3-6. In addition, a property planned examinations, which holds an ordered collection of patient-room pairs, is added to the class medical departments. These model elements reflect the hospital's business process practice to maintain a list of patients waiting for the allocation of a room to walk to and a list of planned examinations, each with a patient waiting for a doctor in an examination room.

Decoupling the allocation of multiple resources

For being more realistic, we consider the fact that patients first need to be walked by nurses to the room allocated to their examination before the examination can start. Thus, in the model of Figure 3-6, we add a second activity type, walks to room, involving people (typically, nurses and patients) walking to an examination room.

This process model describes three causal regularities in the form of the following three event rules:

When a new patient arrives:

- if a room and a nurse are available, they are allocated to the walk of that patient to that room, otherwise a new planned walk is placed in the corresponding queue;

- if a room has been allocated, then the nurse starts walking the patient to the room.

When a walk of a patient and nurse to a room is completed:

- if there is still a planned walk in the queue and a room is available, then the room is allocated and the nurse is re-allocated to the walk of the next patient to that room.

if a doctor is available, she is allocated to the examination of that patient, else a new planned examination of that patient is queued up; - if a doctor has been allocated, then the examination of that patient starts

if the nurse has been re-allocated, she starts walking the next patient to the allocated room.

- if there is still a planned walk in the queue and a room is available, then the room is allocated and the nurse is re-allocated to the walk of the next patient to that room.

When an examination of a patient is completed by a doctor in a particular room:

- if there is still a planned examination (of another patient in another room), then re-allocate the doctor to that planned examination, else release the doctor;

if the waiting line is not empty, re-allocate the room to the next patient, else release the room; - if the doctor has been re-allocated to a planned examination, that examination starts;

if the room has been re-allocated to another patient, that patient starts walking to the room.

- if there is still a planned examination (of another patient in another room), then re-allocate the doctor to that planned examination, else release the doctor;

Notice that the process type described in Figure 3-7 does not consider the fact that doctors have to walk to the examination room too, which could be modeled by adding a doctors' walks to room Activity rectangle after the patients' walks to room Activity rectangle.

For being able to collect informative utilization statistics, it is required to distinguish the total time a resource is allocated (its 'gross utilization') from the time it is allocated for productive activities (its 'net utilization'). Thus, only examinations would be classified as productive activities, while walks to room would rather be considered a kind of set-up activities.

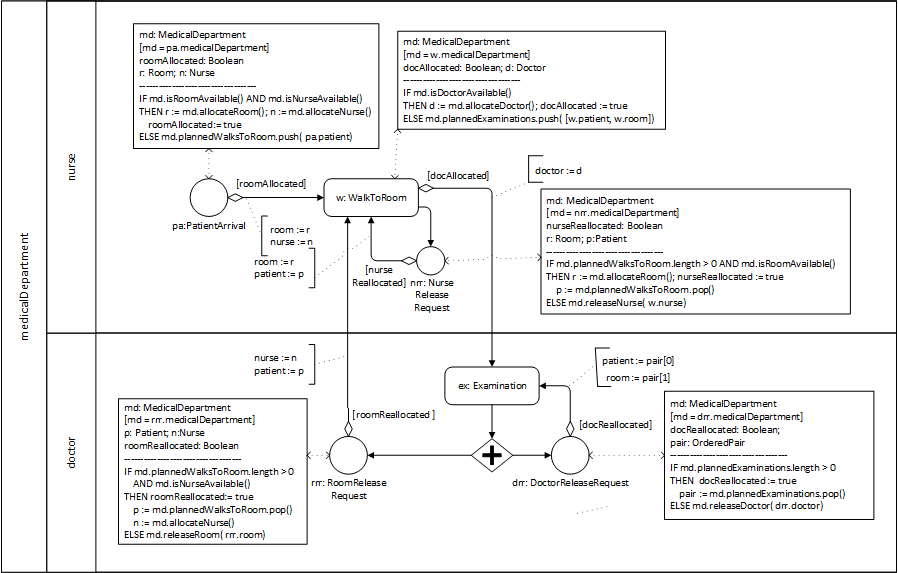

Re-engineering the process type by centralizing the re-allocation of resources

In the process type described in Figure 3-7, the re-allocation of released resources is handled in the event rules of activity end events:

- when a nurse's and patient's walk to a room ends, the nurse is free to be re-allocated; so if there is another planned walk and a room is available, the nurse is re-allocated to a walk of the next patient to that room;

- when an examination ends, its resources (a doctor and a room) are re-allocated, if planned activities are waiting for them.

This approach requires that the same re-allocation logic is repeated in the event rules of all activity types associated with that type of resource, implying that all performers involved would have to know and execute the same re-allocation logic. It is clearly preferable to centralize this logic in a single event rule, which can be achieved by introducing release resource request events following activities that do not need to keep resources allocated, as shown in Figure 3-8 where the re-allocation of doctors and rooms is decoupled from the examination activities and centralized (e.g., in a special resource management unit) by adding the two event types room release requests and doctor release requests modeling simultaneous events that follow examinations.

This process model describes an improved business process with six event rules:

When a new patient arrives:

- if a room and a nurse are available, they are allocated to the walk of that patient to that room, otherwise a new planned walk is placed in the corresponding queue;

- if a room has been allocated, then the nurse starts walking the patient to the room.

When a walk of a patient and nurse to a room is completed:

- if a doctor is available, she is allocated to the examination of that patient, else a new planned examination of that patient is queued up;

- if a doctor has been allocated, then the examination of that patient starts; in addition, a nurse release request is issued.

When a nurse release request has been issued:

- if the waiting line is not empty and a room is available, allocate the room and re-allocate the nurse to the next patient, else release the nurse;

- if the nurse has been re-allocated to another patient, she starts walking that patient to the room.

When an examination is completed:

- [no state change]

- a room release request is issued (e.g., by notifying a resource management clerk or the department's information system), and, in parallel, a doctor release request is issued.

When a room release request is received by a resource manager:

- if the waiting line is not empty and a nurse is available, allocate the nurse and re-allocate the room to the next patient, else release the room;

- if the room has been re-allocated to another patient, the nurse starts walking that patient to the room.

When a doctor release request is received by a resource manager:

- if there is still a planned examination (of another patient in another room), then re-allocate the doctor to that planned examination, else release the doctor;

- if the doctor has been re-allocated to a planned examination, that examination starts.

Notice that, in the general case, instead of scheduling several simultaneous release requests, each for a single resource, when an activity completes, a single joint release request for all used resources should be scheduled, allowing to re-allocate several of the released resources jointly.

Displaying the process owner and activity performers

The process owner and the involved performers can be displayed in an OEM process model by using a rectangular Pool container for the process owner and Pool partitions called Lanes for the involved activity performers, as shown in Figure 3-9. Notice that, as opposed to BPMN, where lanes do not have a well-defined meaning, but can be used for any sort of arranging model elements, DPMN Lanes represent organizational actors playing the resource role of performer.

Non-exclusive resources

In OEM, a resource is exclusive by default, that is, it can be used in at most one activity at the same time, if no parallel participation multiplicity is specified. For instance, in all information models above (e.g., in Figure 3-3), the participation associations between the resource classes rooms and doctors and the activity classes walks to room and examinations do not specify any parallel participation multiplicity (for the association end at the side of the activity class), but just the common (historical participation) multiplicity of "*" expressing that resources participate in zero or more activities over time (without an upper bound).

OEM extends UML Class Diagrams by adding the association end stereotype «parallel» for expressing parallel participation multiplicities.

A non-exclusive resource can be simultaneously used in more than one activity. The maximum number of activities, in which a non-exclusive resource can participate at the same time, is normally specified at the type level for all resource objects of that type using the upper bound of a parallel participation multiplicity. In general, there may be cases where it should be possible to specify this at the level of individual resource objects. For instance, larger examination rooms may accommodate more examinations than smaller ones.

A resource can be exclusive with respect to all types of activities (which is the default case) or it can be exclusive with respect to specific types of activities. For instance, in the model of Figure 3-10, a parallel participation multiplicity of 0..1 is defined both for the participation of rooms in walks and in examinations. This means a room can participate in at most one walk and in at most one examination at the same time, which is a different business rule, allowing to walk patients to a room even if it is currently used for an examination, compared to the model of Figure 3-3, allowing to walk patients to a room only if it is currently not being used for an examination.

3.2. Resource-Constrained Activities in Simulation Design Models

In simulation design models, resource-constrained activities can be modeled in two ways:

- either abstracting away from the structure of resource object types and individual resource objects, and only representing a resource object type in the form of a named resource pool with a quantity (or counter) attribute holding the number of available resources, or

- explicitly representing resource object types and individual resource objects of that type as members of a collection representing a resource pool.

While the first approach is simpler, the second approach allows modeling various kinds of non-availability of specific resources (e.g., due to failures or due to not being in the shift plan).

For any resource object type Res, the three operations described in the following table are needed.

| Resource management operation | General meaning | Resource counter approach | Resource pool approach |

|---|---|---|---|

| isResAvailable | test if a resource of type Res is available and return true or false | test if the corresponding resource counter attribute has a value that is greater than 0 | test if the number of available resource objects in the resource pool is greater than 0 |

| allocateRes | allocate a resource object of type Res | decrement resource counter attribute | select (and return) a resource object from the set of available resource objects in the resource pool (using an allocation policy) and designate it as BUSY |

| releaseRes | de-allocate a resource object of type Res | increment resource counter attribute | take a resource object of type Res as argument and designate it as AVAILABLE |

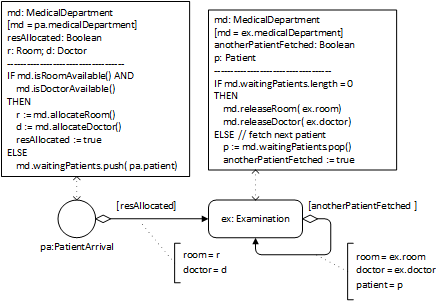

In both approaches, it is natural to add these operations to the object type representing the process owner of the activities concerned, as in the models shown in Figure 3-11 and Figure 3-13.

In the first approach, for each resource object type in the conceptual model, a resource counter attribute is added to the object type representing the process owner and the conceptual model's resource object types are dropped.

In the second approach, the conceptual model's resource object types are elaborated by adding an enumeration attribute status holding a resource status value such as AVAILABLE or BUSY. For each resource object type, a collection-valued property (such as rooms or doctors) representing a resource pool is added to the object type representing the process owner.

A simple model with resource counters

Using the conceptual information model shown in Figure 3-3 as a starting point, we first rename all classes and properties according to OO naming conventions and replace each of the two (conceptual) operations allocate a room and allocate a doctor with a triple of isAvailable/allocate/release operations for the two resource object classes Room and Doctor in the MedicalDepartment class, where we also add the counter attributes nmrOfRooms and nmrOfDoctors. Then, the two resource object classes Room and Doctor are dropped. The result of this elaboration is the information design model shown in Figure 3-11.

Using the conceptual process model shown in Figure 3-4 as a starting point and based on the type definitions of the information design model of Figure 3-11, we get the following process design.

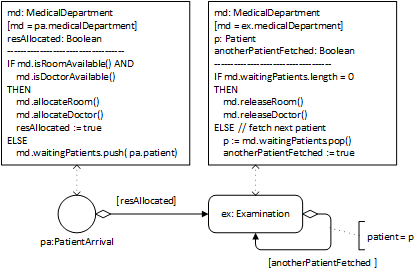

This process model defines the following two event rules.

| ON pa: PatientArrival |

|---|

| md : MedicalDepartment resAllocated : Boolean md := pa.medicalDepartment |

| IF md.isRoomAvailable() AND md.isDoctorAvailable() THEN md.allocateRoom(); md.allocateDoctor(); resAllocated := true ELSE md.waitingPatients.push( pa.patient); resAllocated := false |

| IF resAllocated SCHEDULE Examination( patient:=pa.patient, medicalDepartment:=md) |

| ON ex: Examination |

|---|

| md : MedicalDepartment anotherPatientFetched : Boolean p: Patient md := ex.medicalDepartment |

| IF md.waitingPatients.length = 0 THEN md.releaseRoom(); md.releaseDoctor(); anotherPatientFetched := false ELSE p := md.waitingPatients.pop(); anotherPatientFetched := true |